Ozone installations

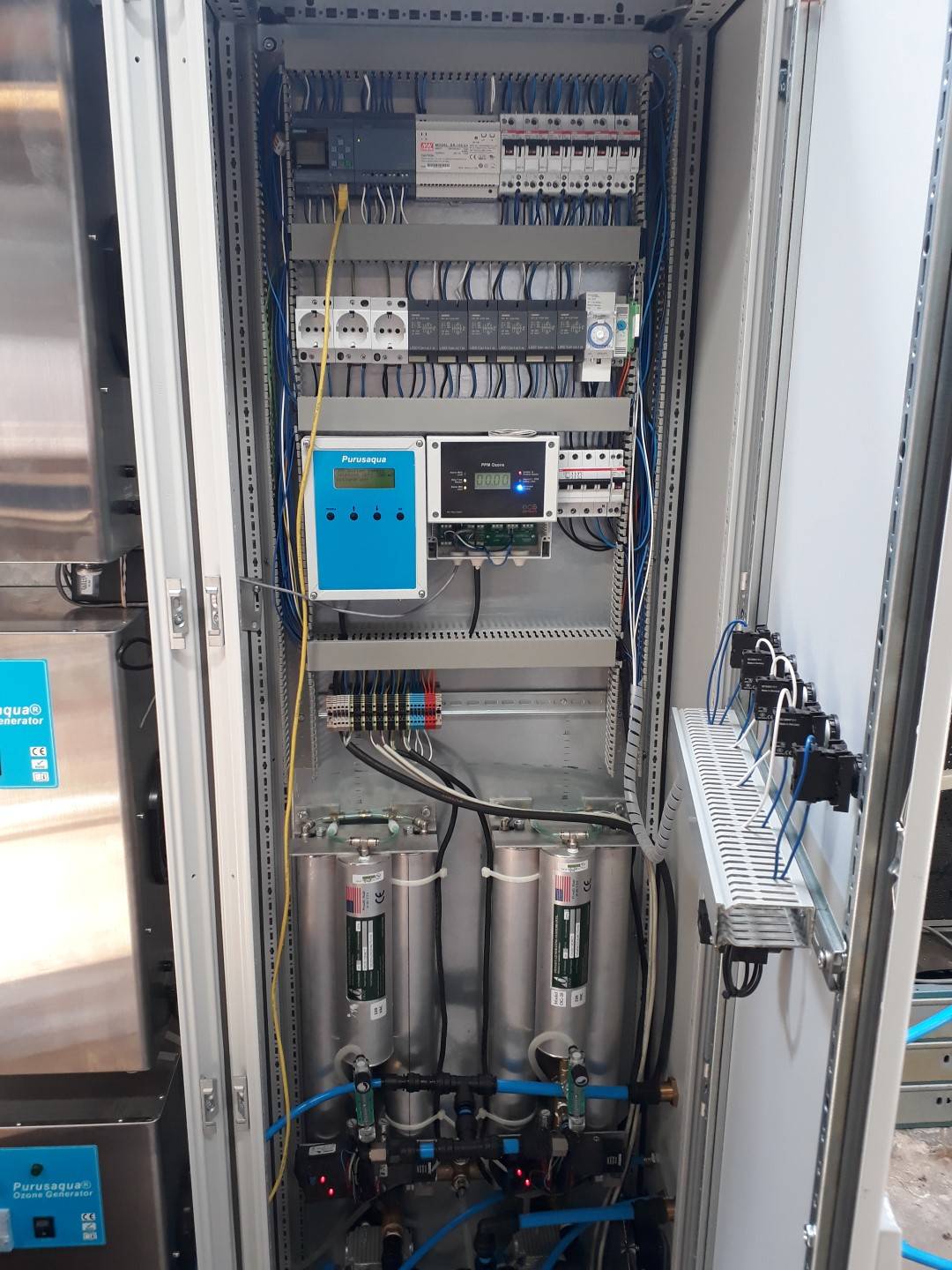

Types of ozone installations

Ozone systems are used in a wide range of sectors. In aquaculture they improve water quality by removing harmful substances such as nitrite and pheromones and by combating pathogens.

In wastewater treatment ozone systems break down persistent contaminants such as chemicals and odours, allowing the water to be reused or safely discharged.

In industry they are applied for disinfection, process‑water treatment and neutralising odours or gases. Each system is tailored to the specific needs of the application, offering benefits such as reduced chemical use, lower operating costs and a more sustainable process.

Ozone installation for aquaculture

The use of ozone in aquaculture offers numerous benefits for both water quality and the health of aquatic organisms. Ozone is a powerful agent that breaks down harmful substances such as nitrite, pheromones and organic waste. As a result the living environment of fish and other aquatic animals is greatly improved, leading to lower mortality and higher productivity.

An important advantage is that ozone eliminates pathogens such as bacteria, viruses and parasites. By removing organic pollution it also lowers oxygen consumption and raises dissolved oxygen levels.

In addition ozone produces crystal‑clear water and prevents biofilm formation. This not only improves animal welfare but also increases the efficiency of filtration systems, leading to lower maintenance costs.

A unique aspect of ozone is that after use it decomposes into oxygen and leaves no harmful residues, making it an environmentally friendly solution.

By deploying ozone, farmers can raise product quality, reduce their ecological footprint and meet the growing demand for sustainable fish and shellfish production.

Our Basic and Compact series ozone generators are ideal for smaller aquaculture systems. For large volumes our HiCon ozone generators are the better choice.

To mix ozone we offer a range of protein skimmers, which also directly remove proteins and organic pollution from the water.

Aquaculture Projects

Ozone for Ouwehands Dierenpark

Two AS400 skimmers with flush computer for Ecomare

Modification of a filter system in a museum about the North Sea

Ozone installation for wastewater

Ozone is increasingly used in wastewater treatment for its strong oxidative properties and environmentally friendly nature. It plays a crucial role in removing contaminants and improving water quality, enabling reuse or safe discharge.

One of the main applications of ozone in wastewater is the removal of organic substances. Ozone breaks these molecules down, significantly reducing the water’s pollutant load. It is particularly effective in treating persistent contaminants such as pharmaceutical residues, pesticides and hormones that are often not removed by conventional methods.

Ozone is also highly suitable for disinfection. It eliminates bacteria, viruses and other pathogens without leaving harmful by‑products, as chlorine does, making ozone a safe choice for both human health and the environment.

Another advantage of ozone is that it removes odours and colourants from the water. This is especially important in municipal wastewater treatment or industrial processes where water reuse is desired.

Ozone treatment requires no chemical storage and therefore carries a low risk. Because of its versatility ozone is applied in both municipal water purification and industrial wastewater management.

Thanks to its effectiveness and sustainability ozone is increasingly recognised as an indispensable solution in modern wastewater treatment strategies.

Due to the often large volumes in wastewater treatment our ozone generators from the HiCon series are particularly suitable.

Wastewater Projects

Ozone system for the pharmaceutical industry

Ozone System for bulb hatchery

Ozone for ozonated water used in the food industry

Industrial ozone installation

Ozone installations for industrial applications provide solutions for a wide variety of processes, from water purification to air treatment. Ozone, a powerful oxidant, is used to remove contaminants, disinfect surfaces and improve the quality of water and air. Thanks to its effectiveness and environmental friendliness these installations find broad applications in various sectors.

In the food and beverage industry ozone installations are deployed for disinfecting surfaces, equipment and packaging. They prevent contamination by bacteria, fungi and viruses without the use of chemicals. They are also applied in water treatment, such as purifying process water and removing odours and flavours.

In the chemical industry ozone plays an important role in oxidation processes. It is used to break down complex compounds, for example in the production of pharmaceutical and chemical products. In some cases this allows water to be reused or discharged.

Ozone installations are also used for air treatment, removing harmful gases, odours and microorganisms from the air, for example at sewage pumping stations, waste processing sites and production processes where odour nuisance is an issue.

Industrial Projects

Ozone system for the pharmaceutical industry

Air treatment with ozone in the packaging industry

Ozone System for bulb hatchery

Ozone for ozonated water used in the food industry

Ozone installation for bottling plants

Ozone plays a crucial role in drinking water bottling plants and soft‑drink production. The process water is disinfected with ozone so that it is free of pathogens.

One of the main applications of ozone in this sector is disinfecting process water. A high‑quality product starts with high‑quality raw water. Ozone leaves no residues, taste, odour or colourants, making it an ideal disinfectant for this sector.

Ozone is also used to disinfect bottles, cans and other containers, ensuring that the product remains free of pathogens after packaging. This guarantees a high quality end product.

Another advantage of ozone is its environmental friendliness. After use it decomposes into oxygen and leaves no harmful residues, contributing to a more sustainable production process. Ozone can also be used to treat wastewater, further reducing environmental impact.